Learn From The Best: Free Equipment Maintenance Log Template For Effective Equipment Tracking

- Key Takeaways

- What is Equipment Maintenance log Template?

- Types of Maintenance Plan Log Sheet

- Benefits of Using an Equipment Maintenance Logs

- Importance of Equipment Lifespan Maintenance

- Importance of Clear Maintenance Log Sheet Records

- Technologies for Maintenance Logs Sheets

- Download Free Equipment Maintenance Excel Spreadsheet Templates

- Conclusion

- Frequently Asked Question

- 1.What is preventive maintenance and why is it important for equipment?

- 2. How effective maintenance practice can contribute to my business?

- 3. How can an equipment maintenance log aid in efficient equipment tracking and management?

- 4. What are the different types of equipment maintenance Schedule commonly used by businesses?

- 5. What procedures should be followed when implementing equipment maintenance?

Are you tired of dealing with frequent breakdowns and unexpected equipment failures? Do you want to improve the efficiency and reliability of your equipment tracking process? Look no further!

In this article, we will show you how to learn from the best by exploring maintenance log examples for effective equipment tracking. By implementing a comprehensive maintenance log system, you can ensure that all your equipment is properly maintained and tracked, reducing downtime and increasing productivity.

A maintenance log is a valuable tool that allows you to keep track of all the activities related to the maintenance and repair of your equipment. It provides a detailed record of each maintenance task performed, including the date, time, technician involved, parts used, and any observations or recommendations. By maintaining a meticulous log, you can easily identify patterns or trends in equipment failures and take proactive measures to prevent future issues. This not only saves you time and money but also extends the lifespan of your equipment.

So why settle for subpar equipment tracking when you can learn from industry leaders who have mastered the art of effective maintenance logging? Let’s dive in!

ServiceFolder's Field Service Management Software provides complete software solutions for back office and field service technicians for the Equipment Maintenance Businesses.

Key Takeaways

• Maintenance logs are important for improving efficiency and reliability of the equipment tracking process.

• Consistent equipment maintenance helps prevent unexpected breakdowns, extends machinery lifespan, and enhances reliability and performance.

• Technology in maintenance logs revolutionizes equipment maintenance records, enabling proactive maintenance and accurate diagnosis.

• Well-maintained equipment operates efficiently, minimizes breakdowns, and benefits from embracing technological advancements in record-keeping practices.

What is Equipment Maintenance log Template?

An equipment maintenance log is a crucial tool for keeping track of repairs and ensuring the proper functioning of machinery. It serves as a detailed record of all maintenance activities performed on different types of equipment.

By using an equipment maintenance log template, you can easily organize information such as the date and time of maintenance, the specific equipment involved, and the nature of the repair or service performed. This log becomes an essential part of your overall maintenance plan, helping you stay on top of regular inspections and addressing any issues promptly.

Maintaining a consistent equipment maintenance schedule is vital to prevent unexpected breakdowns and extend the lifespan of your machinery. With an equipment maintenance log in place, you can create a routine that ensures all necessary checks are done at appropriate intervals. The log acts as a reminder for when certain tasks need to be completed and helps you prioritize which pieces of equipment require immediate attention. By following this schedule diligently, you can reduce downtime due to malfunctions or failures and keep your operations running smoothly.

Furthermore, an equipment maintenance log provides valuable insights into your maintenance management practices. By analyzing the data collected in these logs over time, you can identify patterns or recurring issues that may require further investigation or changes in procedures. The log allows you to track how often specific pieces of machinery require repairs or servicing, enabling you to make informed decisions about replacement or upgrades if necessary.

Additionally, having detailed records readily available makes it easier to comply with regulations or audits related to machinery safety standards.

Utilizing an equipment maintenance log is essential for effective tracking and management of your machinery’s upkeep. It serves as a comprehensive record-keeping tool for all your maintenance activities while providing guidance through scheduled inspections. By analyzing the information within these logs, you can improve your overall maintenance procedures and ensure optimal performance from your equipment while minimizing downtime and maximizing productivity.

Discover more ServiceFolder Features for your

Equipment Maintenance Businesses

Contact Us

Free - 1 User

Types of Maintenance Plan Log Sheet

1. Scheduled Maintenance Log

This type of maintenance schedule logs is commonly used in industries such as manufacturing, transportation, facilities management, and healthcare. It helps in planning and scheduling routine maintenance tasks in advance, ensuring that important activities are not overlooked or forgotten.

The log sheet typically includes information such as the equipment name, identification number, maintenance task description, scheduled date, and any additional notes or instructions. By using a scheduled maintenance log, organizations can ensure that preventive maintenance activities are carried out on time, reducing the risk of equipment failure, optimizing performance, and prolonging the lifespan of the equipment.

It also helps in analyzing trends and patterns in equipment maintenance, identifying any recurring issues or areas for improvement.

2. Maintenance Work Documentation Log

This type of maintenance log is widely used in industries such as manufacturing, construction, utilities, and transportation. It serves as a detailed record of all maintenance work performed on equipment, providing a comprehensive history of repairs, services, and modifications. The log sheet includes information such as the equipment details, maintenance task description, date and time of the work, nature of the repair or service, parts/materials used, labor hours, cost, and the personnel involved.

Maintenance work documentation is crucial for troubleshooting equipment issues, identifying root causes of failures, and evaluating the effectiveness of maintenance strategies. It aids in analyzing maintenance costs, identifying trends in equipment reliability, and making data-driven decisions about optimizing maintenance processes or replacing equipment.

3. Records Maintenance Log

This type of maintenance log is used across various industries where accurate and up-to-date records are essential for compliance, warranty claims, insurance purposes, audits, and legal requirements. It ensures that maintenance activities are properly documented and can serve as evidence that equipment has been regularly maintained as required by manufacturers or industry standards.

The log sheet includes information such as equipment details, maintenance dates, tasks performed, maintenance personnel, and any supporting documents or attachments. Keeping comprehensive records allows for easy reference to past maintenance activities, aiding in future troubleshooting, decision-making, and tracking of recurring issues.

Industries such as aviation, energy, healthcare, and manufacturing heavily rely on records maintenance logs to meet regulatory compliance, demonstrate due diligence, and maintain a reliable history of equipment maintenance.

4. Resale Documentation Log

This type of maintenance log is commonly used in industries where equipment resale or transfer is frequent, such as automotive, construction, and technology. It helps in maintaining a record of regular upkeep, servicing, and repairs performed on equipment, which can be presented to potential buyers or transferred to new owners. It consists of information such as maintenance dates, tasks performed, parts replaced, service provider details, and any warranty or certification documentation.

Having a comprehensive maintenance history increases the credibility and value of the equipment, as it demonstrates proper care, adherence to maintenance schedules, and potentially extended lifespan. Resale documentation logs are particularly valuable when selling used equipment, as they provide potential buyers with confidence in the equipment’s condition and maintenance history.

Beside these popular maintenance log sheet, various industries have created their own maintenance template that suits their business and the type of maintenance work. The importance of equipment log keeps track of all documentation of maintenance work, completed projects and work performed on a specific assist.

Benefits of Using an Equipment Maintenance Logs

One significant advantage of keeping accurate and up-to-date maintenance logs is that they provide a comprehensive record of equipment performance and assist in identifying potential areas for improvement. By documenting all maintenance activities, you can easily track the maintenance history of each piece of equipment. This allows you to analyze patterns and trends in the data, helping you identify recurring issues or areas where proper maintenance may be lacking.

With this information at hand, you can take proactive measures to prevent equipment failure and minimize downtime. Using maintenance logs also streamlines the maintenance process by providing a clear roadmap for technicians. When a piece of equipment requires servicing, the log provides details on previous repairs or inspections performed, making it easier to troubleshoot problems and determine the most effective course of action. Additionally, having a well-documented log ensures that all necessary steps are taken during routine check-ups, reducing the risk of overlooking important tasks.

Another benefit of using maintenance logs is their ability to help control maintenance costs. By tracking all expenses related to each equipment name within the log, you gain insight into the overall cost associated with maintaining different types of equipment. This information enables you to identify any excessive spending on certain items and make informed decisions about optimizing your budget allocation for future repairs or replacements.

Keeping accurate and up-to-date maintenance logs offers numerous benefits in terms of equipment tracking and cost management. They provide valuable insights into equipment performance over time, assist in identifying areas for improvement, streamline the maintenance process for technicians, and aid in controlling overall maintenance costs. Implementing an effective system for recording these logs will undoubtedly contribute to more efficient operations and better long-term planning for your organization’s assets.

Get started with ServiceFolder

- Manage Jobs & Staff

- On Site Quote and Invoice

- On Site Notes and Photos

- Sync with Quickbooks Online

- Print Designer for all Documents

- Equipment/Asset Management

- Customer Management

- Leads Management

- Inventory Management

- Customer Notifications

- Customer Fields

- PriceBooks

Importance of Equipment Lifespan Maintenance

By consistently conducting regular inspections and implementing timely repairs, you can significantly extend the lifespan of your equipment.

One effective way to track and manage equipment maintenance is by using maintenance log examples. These logs allow you to keep a record of all the maintenance activities performed on each piece of equipment, including routine inspections, repairs, and any other necessary actions.

By keeping track of these activities, you can ensure that your machinery is always in top condition and minimize the risk of breakdowns or costly repairs.

There are different types of maintenance logs that you can use depending on your specific needs. For example, an equipment maintenance log allows you to document all the details related to a particular machine’s upkeep. This includes information such as inspection dates, repair history, replacement parts used, and any other relevant data.

By maintaining a well-organized equipment maintenance log, you can easily refer back to it whenever needed and ensure that no scheduled inspections or repairs are missed.

Properly maintained equipment not only extends its lifespan but also increases its resale value. When potential buyers see that your machinery has been well-maintained with detailed records to prove it, they are more likely to trust its reliability and performance.

This can greatly enhance the resale value of your equipment when the time comes to upgrade or replace it. So by investing time in maintaining thorough equipment inspections and keeping accurate maintenance logs, you not only ensure smooth operations but also protect your investment in the long run.

Importance of Clear Maintenance Log Sheet Records

Clean Equipment Track Records

Having clear and organized records of equipment maintenance is like having a well-kept library, where every detail of inspections, repairs, and replacements can be easily accessed and reviewed. When it comes to effective equipment tracking, maintenance log examples play a crucial role. These logs provide a comprehensive record of all maintenance operations performed on the equipment, allowing you to track its history and identify any recurring issues.

By maintaining clear records, you can ensure that your equipment is always in optimal condition. Clear records are important because they allow you to keep track of the kind of maintenance work that has been done on each piece of equipment. This information helps in planning future maintenance operations effectively. For example, by referring to the maintenance log examples, you can determine when certain parts were last replaced or repaired and schedule preventive maintenance accordingly. This proactive approach ensures that potential problems are addressed before they become major issues.

Make Troubleshooting Equipment Easier

In addition to planning future maintenance operations, clear records also help in troubleshooting any problems that may arise with the equipment. By reviewing the maintenance logs, you can quickly identify patterns or trends that may indicate underlying issues. For instance, if multiple instances of the same repair appear in the log for a particular piece of equipment, it could indicate a design flaw or inadequate training for operators. With this information at hand, you can take corrective actions such as modifying procedures or seeking expert advice to prevent further breakdowns.

Effective Team Management

Maintenance log sheets are invaluable tools that greatly assist team members in their work and contribute to efficient maintenance data management. These log sheets serve as comprehensive documentation and references for team members, enabling easy access to information about past repairs, servicing, and maintenance tasks performed on specific equipment.

By referring to these logs, team members can gain insights into equipment maintenance history, identify recurring issues, and make well-informed decisions regarding future actions and necessary upgrades. Additionally, maintenance log sheets aid in planning and scheduling routine maintenance tasks, allowing team members to allocate resources effectively, plan workloads, and ensure timely execution of maintenance activities, minimizing equipment downtime and operational disruptions.

Furthermore, maintenance log sheets facilitate performance analysis and troubleshooting. By providing detailed records of maintenance work, team members can analyze trends, identify patterns, and correlate maintenance activities with equipment performance. This data-driven approach enables team members to evaluate the effectiveness of maintenance strategies, pinpoint areas for improvement, and troubleshoot recurring issues. The log sheets also foster collaboration and communication among team members and departments involved in equipment maintenance, serving as a platform for exchanging information, documenting observations, and sharing insights. This promotes efficient teamwork, reduces duplication of efforts, and ensures consistency in maintenance practices.

Try all in one Equipment Maintenance Businesses Software - Free - 1 UserTechnologies for Maintenance Logs Sheets

Technology has revolutionized the way we maintain and organize records, making it easier than ever to track equipment maintenance with digital logs. With the use of advanced software and applications, maintenance technicians can now create and update their equipment maintenance logs in real-time. This allows for better accuracy and efficiency in recording crucial information about the condition of equipment.

One advantage of using technology for maintenance logs is that it enables proactive maintenance. By regularly inputting data from these checkups into the digital log, technicians can identify patterns and potential issues before they become major problems. This helps in preventing breakdowns or malfunctions by addressing them promptly.

Moreover, technology also allows for scheduling future maintenance tasks based on previous records, ensuring that each piece of equipment receives appropriate care at the right time.

Another benefit of utilizing technology is its ability to provide detailed information about equipment problems. Digital logs can include photographs, videos, or audio recordings that help document any issues encountered during a maintenance check. This visual evidence assists in diagnosing problems accurately and aids in troubleshooting efforts. Furthermore, including the expected time of completion for each task within the log helps create transparency between technicians and other stakeholders involved in the process.

Incorporating technologies in maintenance log sheets has revolutionized maintenance data management, making it more efficient, accurate, and accessible. Advanced software and tech solutions have emerged to streamline the process of recording, organizing, and analyzing maintenance data.

For example, Computerized Maintenance Management Systems (CMMS) such as IBM Maximo, SAP Plant Maintenance, and eMaint provide comprehensive platforms for creating and managing digital maintenance log sheets, allowing team members to easily input and retrieve information, track work orders, schedule tasks, and generate reports.

Furthermore, Internet of Things (IoT) technology has enabled the integration of sensors and connectivity in equipment, providing real-time data on performance and condition. This data can be automatically captured and logged in maintenance log sheets, enabling proactive maintenance and predictive analytics.

Additionally, advancements in mobile applications and cloud-based solutions have made maintenance log sheets accessible on mobile devices, allowing team members to update and access information remotely, collaborate in real-time, and receive notifications and alerts. These technological advancements have significantly enhanced the efficiency, accuracy, and effectiveness of maintenance log sheets, empowering team members with the tools and capabilities to optimize maintenance operations.

Download Free Equipment Maintenance Excel Spreadsheet Templates

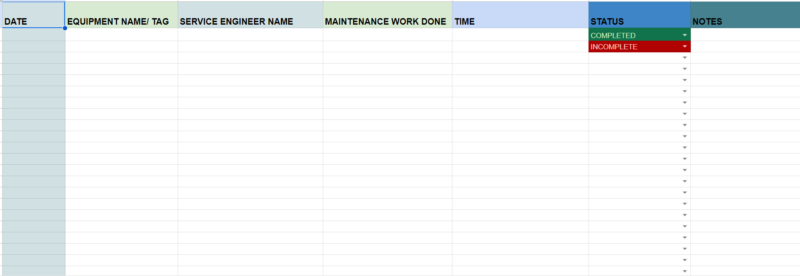

Free Equipment Maintenance Log Template

An equipment maintenance template is an invaluable tool for businesses that rely on various types of machinery to carry out their operations. This template helps track maintenance activities, schedule routine inspections, and record equipment repairs. By utilizing an equipment maintenance template, businesses can ensure optimal performance and longevity of their equipment, leading to increased productivity and reduced downtime.

Free Machine Maintenance Log Schedule Template

Similar to an equipment maintenance template, a machinery maintenance log template focuses specifically on the upkeep of machines and manufacturing equipment. It helps streamline maintenance tasks, such as lubrication, calibration, and parts replacement. By implementing a machine maintenance template, businesses can enhance equipment reliability, reduce breakdowns, and improve overall efficiency.

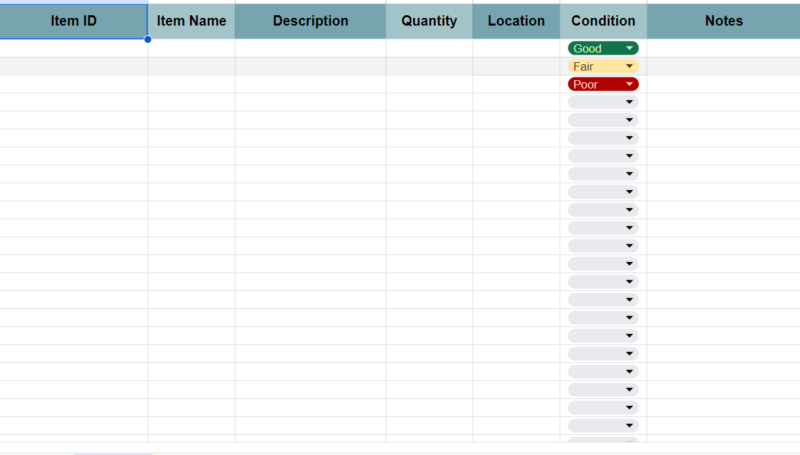

Simple Equipment Inventory Template

Maintaining an accurate inventory of equipment is essential for businesses to efficiently manage their assets. A simple equipment inventory template allows organizations to keep track of equipment details, such as serial numbers, purchase dates, and locations. With this template, businesses can easily monitor equipment availability, plan for replacements, and make informed financial decisions.

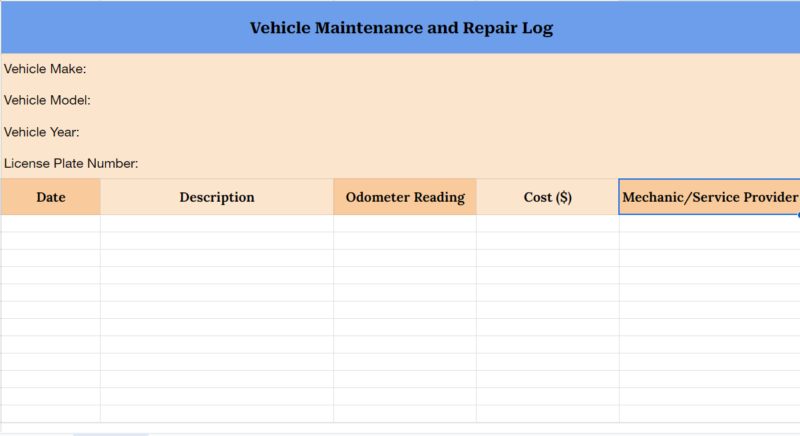

Vehicle Maintenance and Repair Log Template

For businesses that rely on a fleet of vehicles, a vehicle maintenance log sheet template is crucial. It assists in monitoring vehicle maintenance schedules, tracking fuel consumption, and documenting repairs and servicing. By using this template, businesses can optimize vehicle performance, reduce maintenance costs, and ensure compliance with safety regulations.

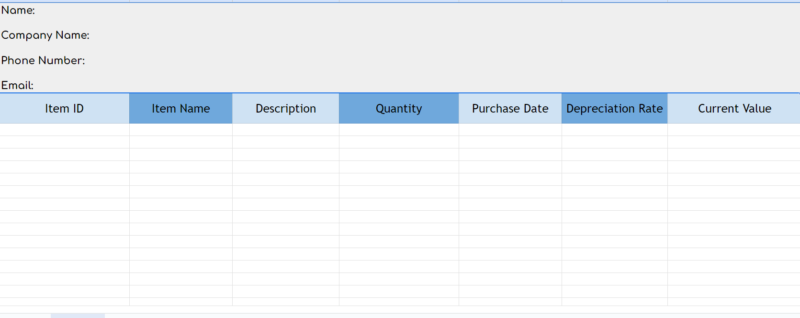

Equipment Inventory and Depreciation Schedule Template

Properly managing and accounting for equipment depreciation is essential for financial planning and reporting. An equipment inventory and depreciation schedule template simplifies the process of tracking equipment values, calculating depreciation, and planning for replacements or upgrades. By utilizing this template, businesses can accurately assess asset value, make informed financial decisions, and comply with accounting standards and other documentation of maintenance.

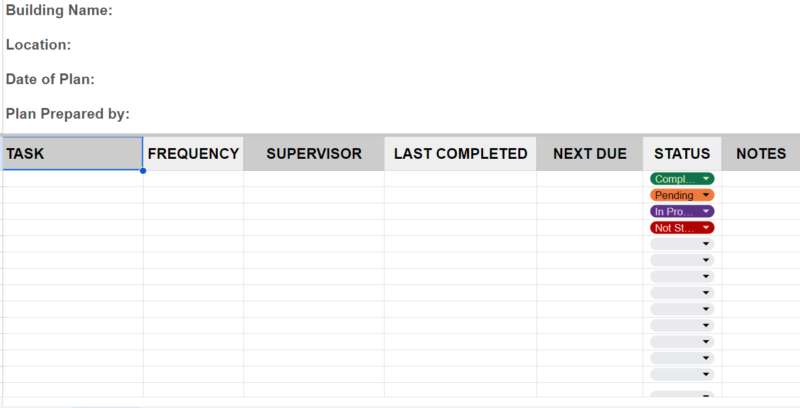

Building Maintenance Work Plan and Log Template

Maintaining the integrity and functionality of a building is crucial for businesses operating in various industries. A building maintenance plan and log template helps organizations schedule and track routine inspections, maintenance tasks, and repairs for their premises. By using this template, businesses can ensure a safe and well-maintained working environment, prolong the lifespan of their facilities, and avoid costly repairs due to neglect

Conclusion

In conclusion, learning from the best is crucial when it comes to effective equipment tracking. By studying maintenance log examples, you can gain insights into how to properly document and track equipment maintenance. This will not only help you keep your equipment in top condition but also extend its lifespan.

Maintenance logs are essential for recording all maintenance activities, including repairs, inspections, and replacements. They provide a clear record of what’s been done and when, allowing you to easily identify any patterns or recurring issues. With this information, you can make informed decisions about preventive maintenance and avoid costly breakdowns.

Moreover, clear and detailed records are important for regulatory compliance purposes. Many industries have specific requirements for documenting equipment maintenance, particularly in areas such as safety and environmental regulations. By maintaining accurate records, you can demonstrate that your organization is meeting these obligations.

Technology plays a significant role in modern maintenance logs. From digital platforms to mobile apps, there are various tools available that streamline the process of capturing and organizing maintenance data. These technologies not only improve efficiency but also enable real-time access to information for better decision-making.

By learning from the best practices showcased in maintenance log examples, you can effectively track your equipment’s health and performance. Maintaining accurate records will contribute to extending the lifespan of your equipment while ensuring compliance with industry regulations. Embracing technology will further enhance your ability to manage and monitor maintenance activities efficiently.

Frequently Asked Question

1.What is preventive maintenance and why is it important for equipment?

Preventive maintenance refers to the regular and systematic inspection, cleaning, and repair of equipment to prevent breakdowns and ensure optimal performance. It is crucial for equipment because it helps avoid unexpected failures, reduces costly repairs, extends equipment lifespan, and improves overall productivity and safety.

2. How effective maintenance practice can contribute to my business?

Equipment plays a vital role in the smooth operation of businesses across various industries. Whether it’s machinery, vehicles, or tools, well-maintained equipment ensures consistent quality output, minimizes downtime, enhances workplace safety, and boosts employee morale. Effective maintenance practices are essential to maximize equipment reliability, minimize disruptions, and ultimately contribute to the overall success and profitability of a business.

3. How can an equipment maintenance log aid in efficient equipment tracking and management?

An equipment maintenance log is a valuable tool that helps track and manage equipment maintenance activities. It provides a centralized record of all maintenance activities, including dates, tasks performed, parts replaced, and any additional notes. By using an equipment maintenance log, businesses can easily track maintenance schedules, identify recurring issues, plan preventive maintenance, track costs, and ensure compliance with regulatory requirements. It streamlines equipment management, improves communication among maintenance teams, and enables informed decision-making.

4. What are the different types of equipment maintenance Schedule commonly used by businesses?

Businesses typically employ three main types of equipment maintenance: reactive maintenance, preventive maintenance, and predictive maintenance. Reactive maintenance involves addressing equipment issues after a breakdown occurs. Preventive maintenance focuses on routine inspections, cleaning, lubrication, and minor repairs to prevent breakdowns. Predictive maintenance utilizes advanced technologies, such as sensors and data analysis, to monitor equipment condition, detect potential failures, and schedule maintenance before any issues arise. The choice of maintenance type depends on factors like equipment criticality, cost implications, and available resources.

5. What procedures should be followed when implementing equipment maintenance?

Implementing effective equipment maintenance involves following a set of standardized procedures. These typically include creating a detailed maintenance plan, scheduling regular inspections, conducting routine cleaning and lubrication, performing necessary repairs or replacements, documenting all maintenance activities in a log, training maintenance staff on proper procedures, and continuously evaluating and optimizing maintenance strategies. It is essential to tailor maintenance procedures to specific equipment requirements, manufacturer recommendations, and industry best practices to ensure equipment longevity and optimal performance.

More Information

Enhancing Equipment Maintenance with ServiceFolder

ServiceFolder (www.servicefolder.com) is an online software solution designed for field service companies. Our Field Service Software streamlines and optimizes operations for industries such as HVAC, Appliance Repair, Chimney Sweep, Cleaning Business, Contractor Business, Electrician Business, Handyman, and Plumbing. Additionally, we offer valuable resources for equipment maintenance needs.

Efficient asset management is crucial, and our blog on Asset Management and Maintenance Software highlights the benefits of specialized software.

Regular auditing of asset management practices is essential, as explored in our blog on Asset Management Audit.

For streamlined asset tracking and field maintenance, our blog on Asset Tracking and Field Maintenance provides insights into specialized software solutions.

Businesses with complex asset management needs can benefit from our enterprise-level solution, which is detailed in our blog on Enterprise Asset Management.

ServiceFolder’s commitment to equipment maintenance encompasses various aspects, including compliance, distributor field service software, and more. Visit our blog on CMMS Compliance to understand its importance.

To address commercial equipment service, we discuss Commercial Equipment Service Software in our blog.

Explore our blog on Asset Management Hierarchy to understand the organizational structure.

For efficient asset tracking, we offer Asset Tracking and Field Maintenance solutions.

Discover the benefits of Commercial Equipment Distributor Field Service Software for seamless operations.

ServiceFolder’s comprehensive software solutions optimize equipment maintenance, ensuring improved efficiency and extended asset lifespan.

Related Posts

Try Now

ServiceFolder's field service scheduling software free plan is perfect for small businesses with up to three people or less. It includes time tracking, scheduling, and mobile app features that make it one of the best mobile field service management software solutions for small businesses available. It is perfect for any small business company within the field service industry that wants to use technology to increase performance and productivity.