How To Streamline Inventory Management In Field Service With Rfid Technology

The field of inventory management has undergone significant transformations in recent years due to the introduction of RFID technology. This technology has been used in many areas, including healthcare, retail and hospitality, with some notable successes reported. This article will explore how RFID technology can streamline inventory management in field service operations. We will discuss this technology’s advantages and why it should be considered for use by field service teams. Finally, we will look at some best practices for implementing and managing RFID-based inventory management systems.

RFID technology is a powerful tool for streamlining inventory management in field service operations. It enables users to quickly identify and locate items within a facility or across multiple sites. Unlike traditional barcode systems, which rely on manual scanning or line-of-sight from a reader device, RFID tags wirelessly use radio frequency signals to transmit information about an item’s location and identity. This allows users to quickly track items without searching through stacks of paperwork or manually searching through warehouse shelves. The main area of RFID tracking is in the field service and retail industry.

In addition to its speed benefits, RFID-based inventory management provides other advantages over traditional methods. It ensures accuracy by eliminating human error during the data entry process and reduces labor costs associated with manually tracking items using barcode scanners or paper records. Furthermore, as it is wireless in nature, it eliminates the need for expensive cabling infrastructure typically required by barcode-based systems. These are just some of the ways that RFID technology can help streamline inventory management in field service operations.

How Does Rfid Work?

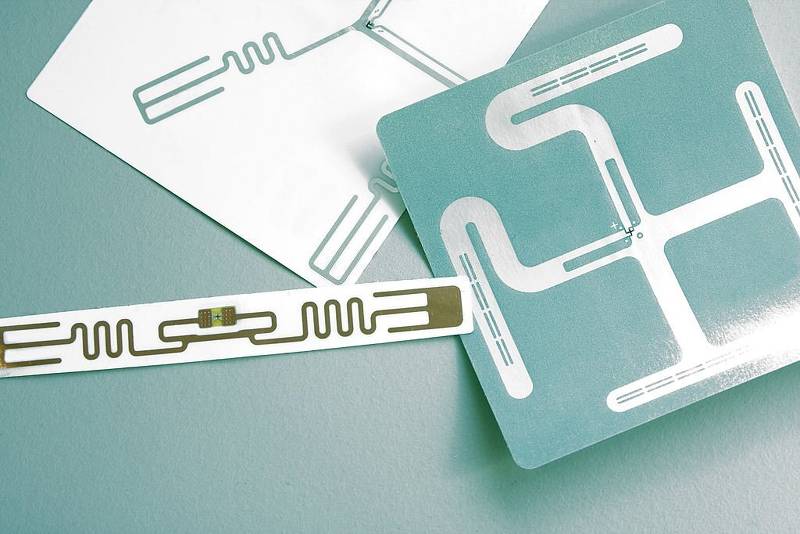

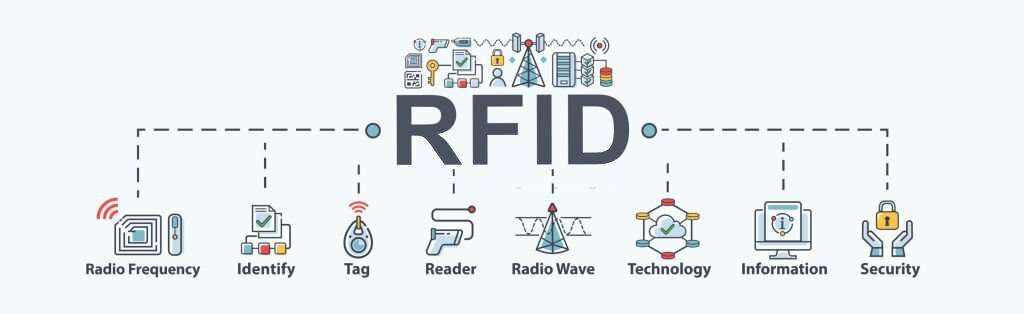

Radio Frequency Identification (RFID) is a technology which uses radio waves to identify objects. It consists of RFID tags, which are small electronic chips that contain an antenna and information about the object it is attached to. An RFID reader can read data from the tag and then transmit it to a computer system. This type of technology has become increasingly popular for use in inventory management, specifically in the field service industry.

RFID tags can be used to track items as they move through various locations, allowing businesses to monitor their inventory levels more effectively than traditional methods of tracking. The readers can also scan multiple tags at once, making the process faster and more efficient than manual methods such as barcode scanning. Additionally, RFID tags have a longer range than standard barcodes, allowing them to be scanned from further away and eliminating the need for physical contact between the reader and the object.

RFID technology is becoming increasingly important for field service companies because it provides real-time data on inventory levels and facilitates efficient stocking processes. This makes it a valuable tool for optimizing inventory management and ensuring customer satisfaction with timely deliveries.

Rfid vs Barcode

Barcode technology uses a combination of bars and spaces to represent data, which a barcode reader can scan. On the other hand, RFID technology uses radio waves to identify and track objects.

One major advantage of RFID scanning technology is that it allows for hands-free scanning and tracking of assets. This means that RFID tags can be read from a distance, without the need for line-of-sight or physical contact. This can save time and reduce errors in the field, particularly when dealing with large or hard-to-reach assets.

Another advantage of RFID technology is that it can store and transmit more data than a barcode. While a barcode typically stores only a few dozen characters of information, an RFID tag can store hundreds of characters or more. This can be particularly useful in field service management, where detailed information about assets and inventory may need to be tracked and recorded.

However, RFID technology can also be more expensive and complex to implement than barcode technology. RFID tags and readers can be more expensive than barcode labels and scanners, and RFID systems may require more infrastructure and setup. In addition, while RFID technology is often more reliable than barcodes, it can still be susceptible to interference from other radio signals or electronic devices.

Advantages Of Rfid Inventory Management For Field Service

RFID technology provides a reliable and efficient way to streamline inventory management in field service. Unlike traditional methods, RFID provides real-time tracking of assets and inventory accuracy, which can save companies time and money while increasing visibility into their inventory movements. Here are the advantages that RFID offers for field service:

Increased Efficiency:

• With an RFID system, businesses can quickly scan items to gather data on inventory levels and movement quickly. This reduces manual labour associated with traditional methods, such as entering data manually or using barcodes. This also allows businesses to reduce errors from manual entry or misreading of bar codes.

• An RFID inventory management system can also be used to automate processes such as reordering supplies when stock runs low, resulting in fewer delays and less downtime for employees due to a lack of materials.

- Operating a passive RFID system over the long term is the low cost of tags.

Enhanced Visibility:

• By having real-time visibility into asset movements, businesses can better monitor their inventory levels and accurately track the location of their assets. This helps prevent lost or misplaced items from interfering with operations.

• Additionally, with an RFID system, companies can easily keep track of when maintenance is due on certain pieces of equipment, ensuring that they are kept in good working order at all times.

With the help of RFID inventory management software, businesses can improve efficiency and visibility when managing their field service inventories. In addition to streamlining operations, this technology eliminates discrepancies that may arise due to manual entry errors or misread barcodes. By implementing an effective RFID system for field service, businesses can ensure that materials are always available when needed and maintenance is done regularly. As a result, companies will experience greater productivity and cost savings in the long run.

Types Of Rfid Inventory Management System In Field Service

RFID technology is an efficient way to streamline inventory management in field service. Modern asset tracking and inventory management systems rely on an RFID subsystem. Various types of RFID systems are available, and they can be used to track items, monitor inventory levels, and increase accuracy.

Active RFID tags are the most common type used in field service as they transmit data over long distances through a reader. These tags typically have a longer range than passive tags, making them ideal for tracking items in large warehouses or during shipping. Passive tags are also popular since they require no power source and can be read from a greater distance than active tags. They can only store information such as item identification numbers but cannot transmit data.

RFID solutions can also include readers which detect radio signals from RFID tags. These readers can be stationary or mobile, depending on the application. Additionally, fixed readers may be placed near entrances or exits to detect any items that pass by with an RFID tag attached. Using RFID technology for inventory management in field service allows for improved accuracy, faster scanning times, and easier tracking of assets. Implementing an effective RFID solution requires careful planning and evaluating all available options to ensure optimal efficiency and cost savings.

How To Implement Rfid For Optimal Efficiency

Implementing RFID technology for inventory management in field service is crucial to ensure optimal efficiency. This can be achieved by using RFID tags, which are small items that contain an embedded radio chip and antenna that can store, receive and transmit data. These tags can be attached to any item, allowing for tracking of the item’s movements throughout the inventory system. There are several steps to implementing RFID for optimal efficiency:

- Selecting the Right RFID System: The first step is to select an appropriate RFID system for your field service needs. Many different types and sizes of RFID systems are available, so it is important to research and compare them before making a decision.

2. Installing the System: After selecting the right system for your needs, the next step is to install it to begin tracking inventory using RFID technologies. This includes connecting all components, such as readers and antennas, setting up databases and software programs, and configuring rules and settings for tracking and monitoring inventory levels.

3. Setting Up Inventory Tracking: Once installed, the next step is to set up the inventory tracking process using RFID tag data collected by scanners or mobile devices connected to the system. This involves creating configuration rules to track each item’s real-time movement within the system properly.

4. Establishing Inventory Control Protocols: Finally, protocols must be established to control access rights, security levels and other parameters related to inventory management with RFID technology. This ensures that all authorized personnel have access only to relevant information related to their job functions while also protecting sensitive data from unauthorized users and enabling smart inventory management.

By following these steps, organizations can optimise their field services with an efficient inventory management process using RFID technology. Furthermore, this will allow them greater visibility into their operations and improved inventory control through automated tracking of items within their inventory system. With the proper implementation of an effective RFID-based inventory management strategy, organizations can reap numerous benefits from automated inventory management processes within their field services operations.

Benefits Of Automated Inventory Management: Application of Rfid

Automated inventory management has numerous benefits, and RFID technology work has been instrumental in streamlining the process. Accurate inventory tracking can be achieved with an automated system, eliminating manual errors and improving overall accuracy. With the ability to monitor stock levels more precisely, organizations can identify shortages and take appropriate action to replenish supplies before they run out.

Automated inventory systems also make it easier to manage warehouses; a warehouse management system can track products from when they enter the warehouse until they are shipped out. This allows for better decision-making regarding where to store items and forecasting upcoming demand. Improved visibility of stock levels also reduces the need for regular physical inventories, saving time and money in labor costs associated with manually counting items.

Additionally, RFID technology makes it possible to track assets in real-time, allowing managers to identify misplaced or stolen items and take corrective action quickly. Overall, automated inventory management systems that integrate RFID inventory management solutions offer numerous benefits that improve both efficiency and accuracy of inventory tracking systems and better inventory control.

Challenges With Automated Inventory Management and Rfid Technologies

As the previous section illuminated, automated inventory management can be a major boon to field service businesses. However, it is not without its challenges. One of the most significant obstacles faced with automated inventory management is the accuracy of data collection. Inventory transactions, processing, and information are all rendered ineffective without precise and accurate data. RFID technology is often used to collect data accurately and efficiently. This can allow businesses to manage inventory more smartly by tracking and counting items automatically as they’re removed from or added to the inventory system.

However, there are still potential issues with RFID technology. If a tag malfunctions or fails to read correctly, it may lead to incorrect information being recorded in the system and disturb the entire supply chain. Additionally, while RFID tags can identify items quickly and accurately in large batches in a short period compared to manual processes, they are also expensive and require regular maintenance and upkeep for them to remain effective.

Finally, another challenge businesses face with automated inventory management systems is preventing employees from making mistakes when entering data into the system. Incorrectly entered data could potentially negate the value of using an automated system altogether and create costly errors if not addressed quickly. This will lead to confusion in inventory and asset management.

Strategies For Ensuring Accuracy In Data Collection

RFID technology is used as an effective tool for streamlining inventory management in field service, as it allows for real-time inventory data to be captured quickly and accurately. By utilizing handheld RFID readers and tags attached to assets, organizations can track the location of their inventory in real-time, allowing them to maintain proper inventory levels and reduce loss or theft. Additionally, RFID readers can also be used to capture data from multiple sources simultaneously, making it easier to analyze and monitor trends in inventory usage.

Integrating RFID technology into inventory management systems also helps organizations ensure accuracy when collecting and tracking data. By using RFID tags that are linked to specific items, organizations can easily identify the location of their assets and track their movement throughout the supply chain. This information can then be used to quickly update inventory levels and detect any discrepancies in stock levels before they become a problem. Additionally, by automating the process of collecting and updating data, organizations can minimize human errors related to manual data entry.

By utilizing RFID technology as part of their overall inventory management strategy, organizations are able to improve accuracy when collecting data on their assets while also gaining valuable insights that can help them better manage their inventories in the long run. This improved accuracy will help ensure that organizations have a clear understanding of their current stock levels at all times, enabling them to make informed decisions about ordering new products or reducing excess stock. Transitioning into ongoing maintenance and support of this system is key for long-term success with field service operations.

Ongoing Maintenance And Support

Implementing an asset tracking system through RFID technology in field service inventory management is an effective way to streamline operations. Its utilization provides various benefits, including real-time data collection, asset tracking, accuracy, and visibility. However, ensuring that all components are properly maintained and supported is important. Here are some tips for ensuring the ongoing success of your RFID system:

• Utilize a reliable RFID handheld device that has been tested for accuracy and compatibility with your chosen software.

• Ensure that the asset management software you’re using keeps up with new updates in order to maintain its effectiveness.

• Invest in a comprehensive inventory solution that includes tracking software, supply chain management capabilities, and other features as needed.

• Periodically check the tags used to track assets for damage or wear and tear.

• Consider additional training for employees who will be using the system to ensure they are familiar with its use.

These steps can help ensure that you get the most value from your RFID technology investment by keeping it functioning optimally over time. Additionally, these steps should also be incorporated into any future plans for expanding your RFID system usage by adding new components or features as needed. Taking these measures can help you stay ahead of potential problems before they arise, allowing your business to take full advantage of RFID technology in field service inventory management.

Conclusion

In conclusion, RFID technology provides field service teams with a powerful tool for streamlining inventory management. By implementing the right type of RFID system, businesses can benefit from improved accuracy in data collection and automated inventory tracking. According to a survey of leading companies in the field service industry, these benefits have been shown to result in an average of 35% reduction in inventory costs. Additionally, ongoing maintenance and support is essential for ensuring accurate data collection and optimal efficiency. With proper implementation and maintenance, **field service organization**s can leverage the power of RFID technology to improve inventory management and drive operational performance.

Related Posts

Try Now

ServiceFolder's field service scheduling software free plan is perfect for small businesses with up to three people or less. It includes time tracking, scheduling, and mobile app features that make it one of the best mobile field service management software solutions for small businesses available. It is perfect for any small business company within the field service industry that wants to use technology to increase performance and productivity.